SiC wafer, namely silicon carbide wafer, is a semiconductor wafer based on silicon carbide material. Compared with ordinary silicon wafers, silicon carbide wafers have the following characteristics: Higher thermal conductivity: The thermal conductivity is much higher than that of silicon, which can dissipate heat more effectively and is suitable for working in high-temperature environments. Higher electron mobility: The electron mobility is higher than that of silicon, enabling devices to operate at a higher speed. Higher breakdown voltage: Suitable for manufacturing semiconductor devices for high-voltage applications. Higher chemical stability: Stronger resistance to chemical corrosion helps improve the reliability and durability of devices. Wider energy gap: The energy gap is wider than that of silicon, which makes the device have better performance and stability at high temperatures. Better radiation resistance: Suitable for use in radiation environments such as spacecraft and nuclear energy facilities. Higher hardness: Helps improve the durability of the wafer during processing. Lower dielectric constant: Helps reduce parasitic capacitance in devices and improve high-frequency performance. Higher saturation electron drift velocity: Has advantages in high-frequency applications. Higher power density: Due to the above characteristics, higher power output can be achieved in a smaller size. The application fields of silicon carbide wafers include but are not limited to: New energy vehicles: It can significantly optimize the efficiency of the electric drive system of automobiles, help charging piles and on-board chargers withstand greater charging power, reduce the energy replenishment time, and can also be applied to on-board chargers, DC-DC converters, BMS relays and air conditioning compressors, etc., comprehensively improving the performance, reliability and stability of new energy vehicles. Wind and solar energy storage: Applied in wind turbines, photovoltaic inverters, and energy storage converters, it can significantly improve the energy conversion efficiency and reliability of the system, and extend the service life of the equipment and reduce the volume and weight of the equipment to achieve a lower cost per kilowatt-hour. Its excellent radiation resistance and corrosion resistance characteristics can also effectively improve the benefits of photovoltaic power generation and wind power in harsh environments such as at sea and on plateaus. Rail transit: Applied in the rail transit traction converter system, it can increase the efficiency of the traction converter equipment by more than 10%, meet the requirements of large capacity, lightweight and energy-saving of rail transit for the application of traction converter equipment, enhance the overall efficiency of the system, and can also break through the silicon-based limit and further improve the performance and reliability of the rail transit traction system. Electric power and smart grid: Server power supplies and UPSs using silicon carbide devices can reduce system energy consumption, maintain stable power supply, and empower the intelligent development of society. The large-scale introduction of silicon carbide power electronic transformers in flexible DC transmission equipment can greatly simplify the circuit topology, significantly reduce the device volume, improve the transmission and transformation efficiency, and help the reconstruction of the smart grid. 5G communication and national defense: Silicon carbide-based gallium nitride radio frequency devices have good thermal conductivity and the advantages of high efficiency and high power density at high frequencies. They can help 5G base stations achieve lightweight, active, and multi-channel, and become the mainstream choice for 5G base station power amplifiers. It can also help high-performance radars achieve miniaturization, high efficiency and high reliability, and has important development in fields such as aerospace, meteorological monitoring, and military industry. The manufacturing process of silicon carbide wafers is different from that of silicon wafers and requires specific equipment and technologies. At present, its production cost is relatively high, but with the progress of technology and large-scale production, its applications are expected to become more and more widespread. Some companies in China are in a leading position in the silicon carbide wafer industry. For example, Beijing Tianke HeDa Semiconductor Co., Ltd. is one of the first national high-tech enterprises in China engaged in the research and development, production and sales of third-generation semiconductor silicon carbide single crystal substrates and related products. Its products cover the entire production process of silicon carbide semiconductor materials, including silicon carbide substrates, epitaxial wafers, powders, crystals and single crystal growth furnaces of different sizes and types. It has initially formed an industrial layout based on the three core advantageous regions of Beijing-Tianjin-Hebei, Yangtze River Delta, and Guangdong-Hong Kong-Macao Greater Bay Area, radiating and driving the whole country. If you want to know more detailed information about silicon carbide wafers or have specific purchase needs, it is recommended to contact relevant professional manufacturers or suppliers for consultation. Contact number: +86-186-37150220, business QQ: 578536, email: rainimp@163.com website: [http://www.kjsw.com]. Silicon carbide wafers of different manufacturers and specifications may have differences in price. The specific price needs to be further confirmed with the supplier.

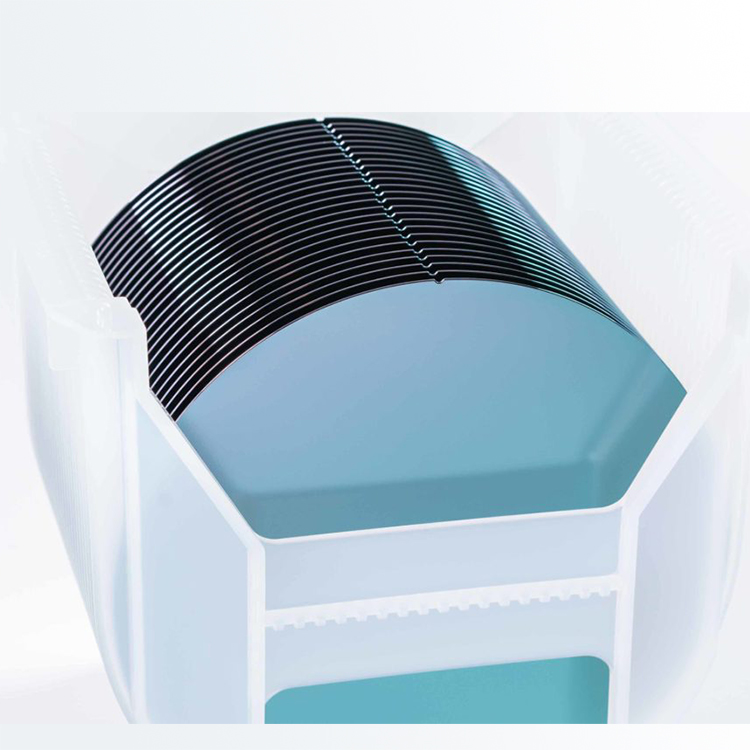

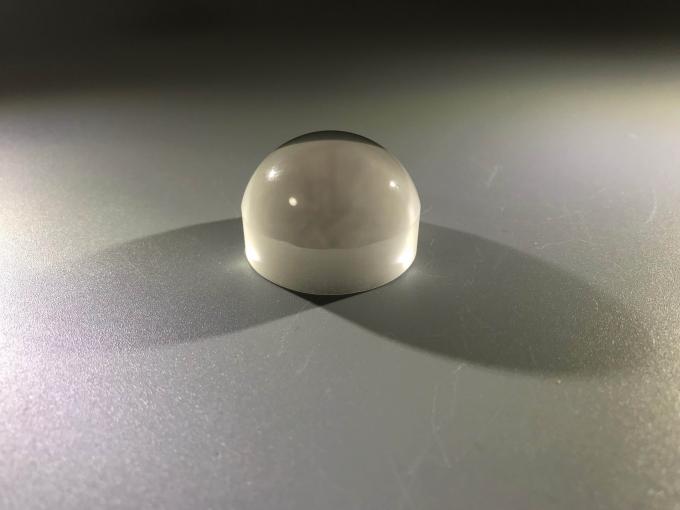

6 inch diameter Silicon Carbide (SiC) Substrate Specification p-type 4H/6H-P 3C-N TYPE SIC substrate 4inch 〈111〉± 0.5°Zero MPD The different between 4H-SEMI sic substrate and 4H-N sic substrate