Here are some ways to determine whether a wafer cassette is well-sealed:

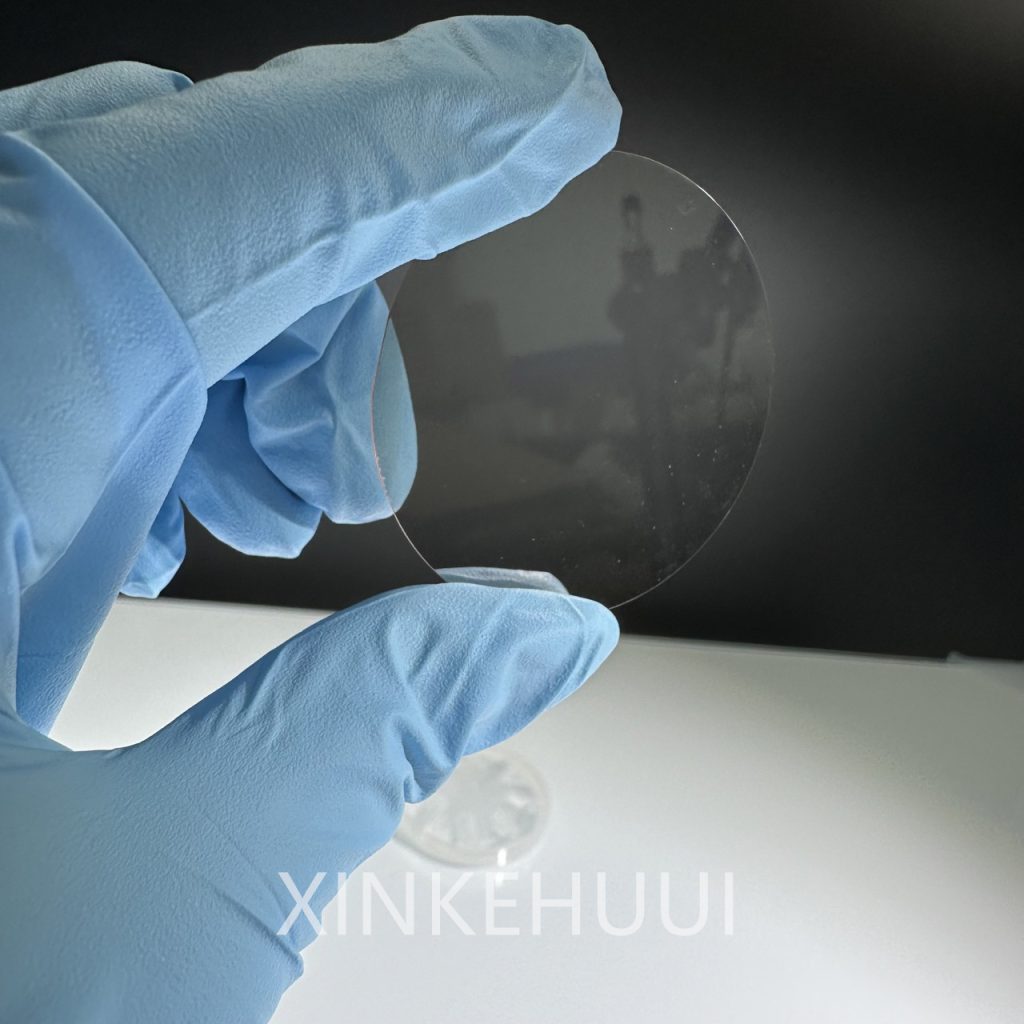

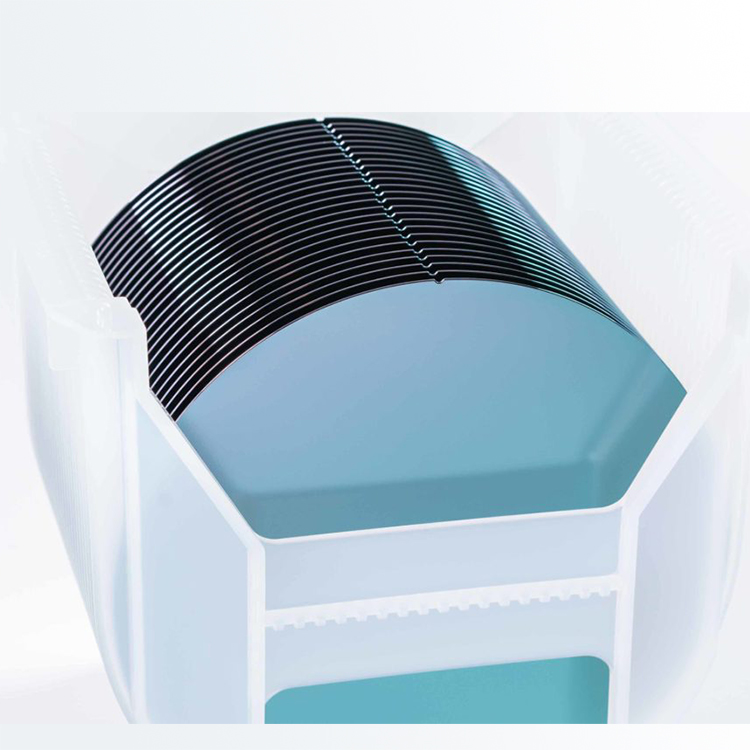

Visual Inspection

Examine the wafer cassette carefully. Look for any gaps or openings between the lid and the body of the cassette. A properly sealed wafer cassette should have a tight fit with no visible spaces where air or contaminants could enter.

Examine the wafer cassette carefully. Look for any gaps or openings between the lid and the body of the cassette. A properly sealed wafer cassette should have a tight fit with no visible spaces where air or contaminants could enter.

Pressure Test

In some cases, a pressure test can be conducted. This might involve using a pressure sensor or gauge to detect if there is any change in pressure inside the cassette when a certain amount of pressure is applied from the outside. If the pressure remains stable, it indicates good sealing.

In some cases, a pressure test can be conducted. This might involve using a pressure sensor or gauge to detect if there is any change in pressure inside the cassette when a certain amount of pressure is applied from the outside. If the pressure remains stable, it indicates good sealing.

Leak Detection

There are specialized leak detection equipment and methods available. For example, helium leak detection can be used in some advanced semiconductor manufacturing facilities. Helium is a very small molecule and can detect even the tiniest leaks. If no helium is detected escaping from the cassette, it suggests good sealing.

There are specialized leak detection equipment and methods available. For example, helium leak detection can be used in some advanced semiconductor manufacturing facilities. Helium is a very small molecule and can detect even the tiniest leaks. If no helium is detected escaping from the cassette, it suggests good sealing.

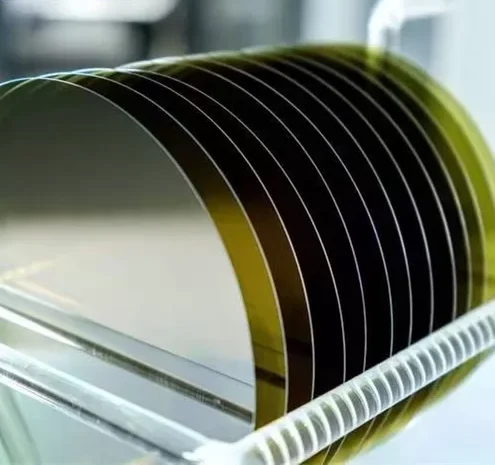

Check for Contamination

After a period of storage or transportation, inspect the wafers inside the cassette for any signs of contamination. If there is no dust, moisture, or other contaminants on the wafers, it is a good indication that the cassette has been sealed properly and has protected the wafers from the external environment.

After a period of storage or transportation, inspect the wafers inside the cassette for any signs of contamination. If there is no dust, moisture, or other contaminants on the wafers, it is a good indication that the cassette has been sealed properly and has protected the wafers from the external environment.