Indium phosphide (InP) semiconductor has the following advantages and disadvantages:

Advantages:

Advantages:

- High electron mobility: This enables InP to perform outstandingly in high-frequency applications, achieving rapid signal processing and transmission. It can be used to manufacture high-speed electronic devices such as high electron mobility transistors (HEMT), millimeter-wave and microwave devices124.

- Large bandgap: It has a relatively high breakdown electric field strength, suitable for the fabrication of high-power, high-temperature, and high-frequency electronic devices. Moreover, its wide bandgap structure allows the device to work stably in high-temperature and harsh environments123.

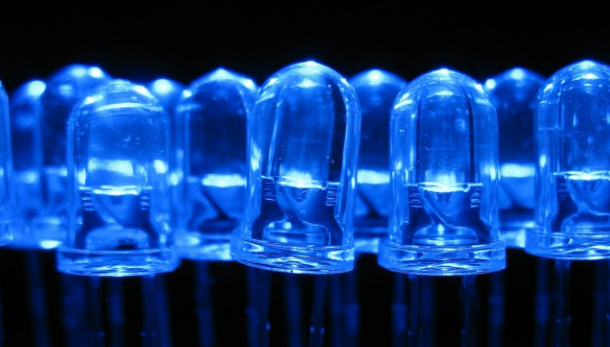

- Excellent photoelectric properties: InP has good luminescent properties and light absorption characteristics, making it an ideal material for manufacturing semiconductor lasers, photodetectors, solar cells and other optoelectronic devices. For example, in the field of optical communications, InP can be used to make lasers and detectors in optical fiber communication systems to realize high-speed and large-capacity optical signal transmission278.

- High saturated electron drift velocity: It is beneficial for high-speed electronic device operation257.

- Strong anti-radiation ability: It can maintain stable performance in radiation environments, which is important for some special application scenarios such as aerospace28.

- Good thermal conductivity: Facilitates the dissipation of heat generated during device operation, helping to improve the reliability and performance stability of the device28.

Disadvantages:

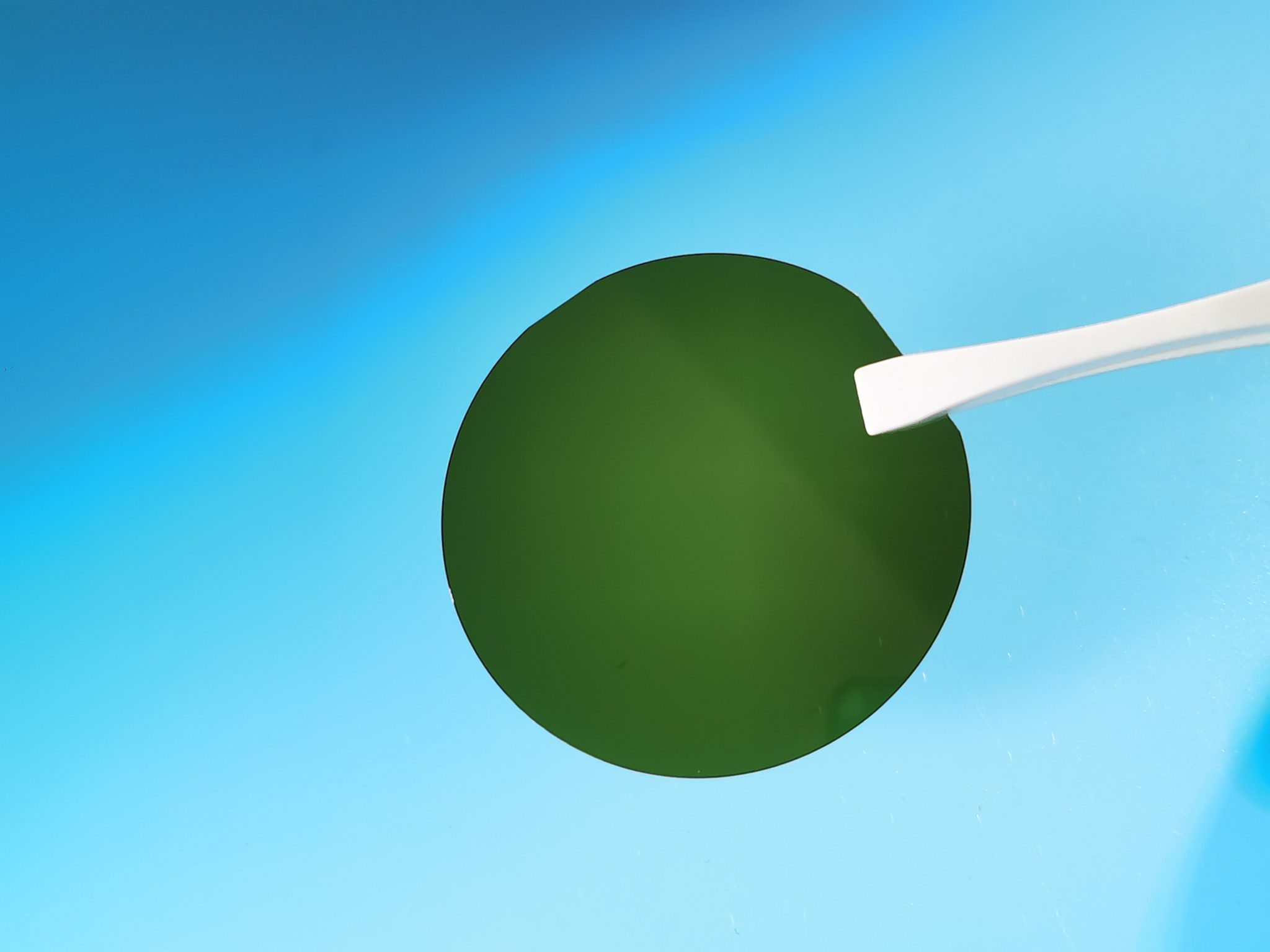

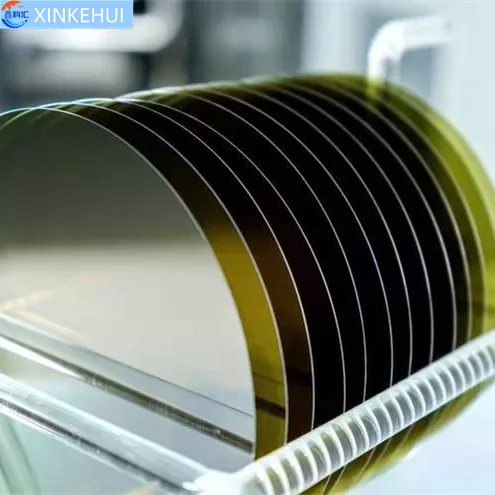

- Fragility: The wafer of InP is relatively fragile, which increases the difficulty in processing and handling, and may lead to a higher risk of damage during the manufacturing process3.

- High production cost: The complexity of the material and the difficulty of manufacturing processes result in relatively high production costs, which may limit its widespread application in some cost-sensitive fields3.

- Difficulty in large-scale production: Compared with some common semiconductor materials such as silicon, the technology and process for large-scale production of InP are more challenging, resulting in a relatively small production scale and a high degree of market concentration3.

- Limited availability of raw materials: The availability of indium, one of the main raw materials for InP, may be limited to some extent, which could affect the large-scale production and cost of InP in the long run